Tech

Moore is more than meets the eye: The evolution of computing

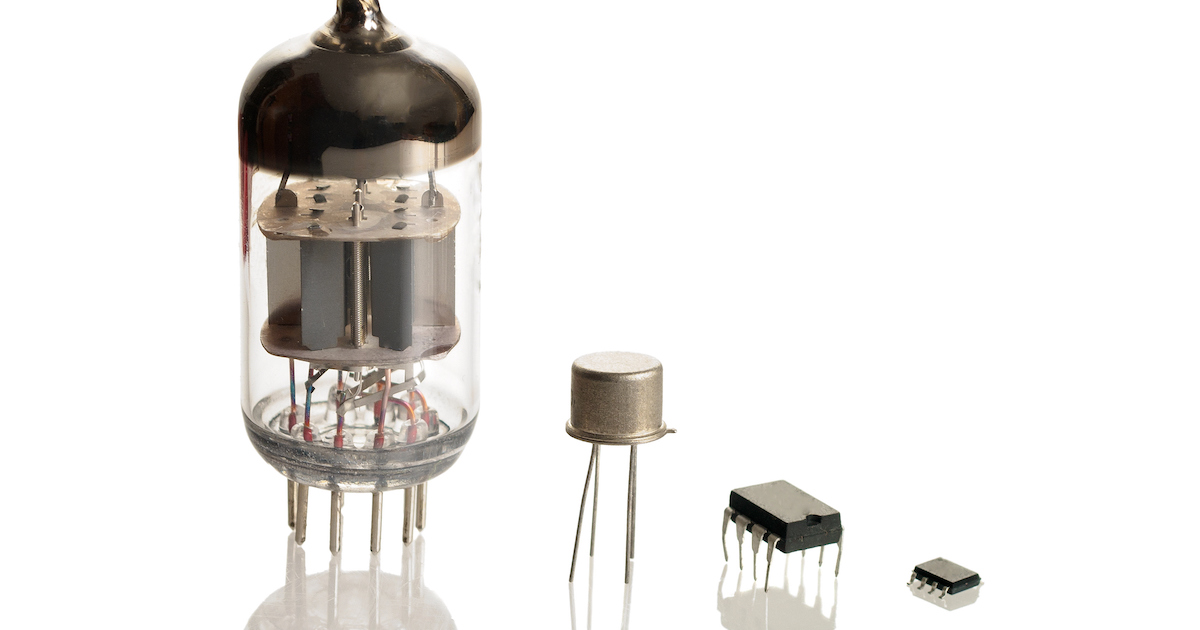

Transistors replaced vacuum tubes in the mid-20th century. They were first made of germanium and later of silicon, leading to the development of integrated circuits containing millions to billions of transistors on a single chip. Metal Oxide Semiconductor Field Effect Transistors (MOSFETs) has become the dominant type due to its small size, high speed and high energy efficiency. Today, MOSFETs are essential components in modern electronic devices such as computers, smartphones and power electronics. (Image: iStockphoto/vlabo)

After the COVID-19 pandemic disrupted global supply chains, it became clear that many aspects of modern life are secretly dominated by tiny technologies known as semiconductor chips. From mobile phones and refrigerators to fighter planes, these tiny, flat semiconductor materials play a vital role in facilitating data processing and storage.

Chips are seemingly ubiquitous, but seemingly complicated. At the heart of these small but increasingly powerful technological evolutions is a principle known as Moore’s Law, named after Gordon Moore, the engineer who co-founded Intel his corporation. Penn Today spoke with the School of Engineering and Applied Sciences Ben Lee to discuss the rapid evolution of computers and consider Moore’s important work, who passed away in March.

A brief history of chips

The story of the chip begins in Silicon Valley in the late 1950s, when engineers began to explore the special properties of silicon, Lee says. Information he relays as 1s or 0s and forms the basis of computing.

By the early 1960s, engineers at the technology company Fairchild Semiconductor were trying to find ways to improve computers by adding more and more transistors to the semiconductor chips that process and store information. One of the people who made a name for himself in this field was Gordon Moore.

Moore, co-founder of Fairchild and co-founder of Intel, has observed that the number of circuit components that can be put on a chip doubles at a steady rate about every 18-24 months. is famous. This became known as Moore’s Law and set the rhythm of modern progress in computing from 1965 until his mid-2000s.

Moore’s first observations were economic and empirical, Lee says. Moore argued that component integration reduces costs, and that over time, the most cost-effective integrated circuits will be those that integrate more components. This observation has been true for decades and has driven rapid advances in computer technology.

how they keep improving

Lee says a phenomenon called Dennard scaling played a big role in shaping the evolution of chips.

IBM chip designer Robert Dennard has proposed a set of guidelines for miniaturizing transistors, says Lee. Dennard argued that operating voltages must scale with transistor size, allowing both chip size and power consumption to shrink.

So smaller transistors, which allow more transistors to fit on a chip, are faster, more energy efficient, and offer better computing power and memory, says Lee. And all this happens from generation to generation at an unprecedented pace. It’s like building a plane that gets twice as fast as he does with each iteration.

Lee points out that Cadence Law lasted much longer than Dennard and Moore expected. However, in the mid-2000s they began to slow down as the structures needed to keep up with processing demands began to challenge the laws of nature.

The physical limits of transistor miniaturization are due to several factors. Some of them are sub-atomic, such as sub-threshold current, where electrons leak through thin barriers in transistors. Such a situation can cause power and reliability problems, Lee said.

As a result, Intel and others have started developing a series of ad hoc design methodologies that are passed down from one generation to the next, he says.

To improve performance without significantly increasing power consumption, chip designers turned to new transistor designs, Lee said. It essentially switches from the industry-standard flat planar structure to a more three-dimensional design, incorporating a vertical geometry that helps control the movement of electrons.

The manufacturing technology behind the most sophisticated transistors is often defined by its process node, says Lee. A number that refers to the minimum size of a transistor or other component on a chip. Like 5 nanometers versus 3 nanometers, the smaller the number, the more sophisticated and powerful the chip. These numbers have become a way of tracking advances in chip technology.

How the Transistor Gets to the Chip

Lee explains that the chip manufacturing process often begins in the US or UK, with companies such as Apple and Arm developing chip designs. Often these blueprints are then sent to a Taiwanese company known as Taiwan Semiconductor Manufacturing Company (TSMC). TSMC prints or manufactures 300-600 of these designs on round silicon wafers, typically hundreds of squares. mm size. Each of the fingernail-sized chips on these wafers can hold tens of billions of transistors.

TSMC is special because it now has the most advanced semiconductor manufacturing capacity in the world, Lee said. They are currently manufacturing chips at the 5-nanometer scale and plan to manufacture the next node at 3-nanometer later this year.

These metrics no longer directly refer to the actual length or dimensions of the transistors on the chip. Rather, Lee says, he quantified the industry’s progress in manufacturing more advanced transistors in a constant rhythm that was first inspired by Moore. But that doesn’t take away from the fact that nanometer-scale transistor technology is a major engineering feat. In general, viruses range in diameter from 20 to 400 nanometers.

Advanced semiconductor manufacturing requires scientists and engineers to devise new ways to manipulate materials at the atomic level to sustain advanced computational power, Lee explains.

The chips are then cut from the wafer and sent to various countries in Southeast Asia and China for assembly, testing, and packaging into devices such as mobile phones and computers.

A little bit about printers

Underlying chip creation are two more important processes. It’s the manufacture of printers and the manufacture of their components, he says Mr. Lee. These steps are probably the most expensive and require a high degree of precision to perform.

Manufacturing chips at the process node requires a technique known as extreme ultraviolet photolithography. In this technique, ultraviolet light is emitted from a piece of machinery and reflected by a series of mirrors to pattern chip designs onto silicon wafers. It resembles a high-tech stencil that uses light to draw intricate designs onto a surface.

My understanding is that it’s an incredibly complex process, and only one Dutch company, ASML, can manufacture printers for the most advanced chips, says Lee. Without these ASML machines, chips cannot be manufactured at the most advanced process nodes.

Printer manufacturing is also highly specialized, with only a few companies in the world designing and manufacturing the necessary parts. For example, Carl Zeiss in Germany and Nikon and Canon in Japan provide lenses and mirrors, while Lam Research and Applied Materials in the US provide etching systems and other tooling components. Companies within this key segment of the industry that have created large, integral companies focused on specific parts of the manufacturing process, Lee says.

How Hardware Advancements Affect Software

The impending transition from 5-nanometer to 3-nanometer process technology will heed the principles outlined by Moore and Dennard, Lee says. Advances in process technology will allow him to integrate more components into a single chip. Tighter integration traditionally means more computing power and less packaging costs.

According to Lee, the reason has to do with freeing up space for adding processor units or cores to the chip. He explains that chips contain a kind of fast memory for frequently accessed data called cache, similar to the short-term memory of the human brain. They both store information temporarily to perform complex tasks, and once completed, that data is discarded or sent to long-term storage. Therefore, the larger the cache, the more operations can be performed directly on the chip.

Some of these scale reductions immediately benefit software, Lee says, because hardware needs to move data over shorter distances. These advances could also improve the efficiency of data center servers, he speculates.

However, he clarifies that he doesn’t necessarily believe that the move from 5-nanometer to 3-nanometer will lead to fewer machines in data centers in the short term. Instead, it opens the door to storing and processing more data in a single enclosure compared to multiple interconnected devices. This reduces energy costs and improves performance for cloud-based artificial intelligence applications.

A lot of people are talking about a little machine learning, Lee says. The idea here is to scale the model, or the essence of the model, so that it fits on a handheld device.

You can’t get ChatGPT-like functionality on your phone right now, but one day you’ll get chips that try to emulate the behavior of neurons, neuromorphic accelerators, and chips that run a scaled-down version of AI. There are cases where it is possible to Pattern recognition and anomaly detection can all be done in a small device.

Closing remarks

Advances in semiconductor manufacturing continue to impact supply chain management and underlying technology. However, computer architects and chip designers must translate these technologies into high-performance, energy-efficient systems that support future software applications.

Researchers have repeatedly predicted the demise of Moore’s Law and technology scaling, only to be surprised by continued advances in manufacturing technology, says Lee. Still, chip designers are working to enable continued growth in performance and power efficiency through better designs customized for specific classes of computation and qualitatively new technologies beyond today’s transistors and circuits. , is beginning to explore the Beyond Moore strategy.

|

Sources 2/ https://penntoday.upenn.edu/news/moore-meets-eye-evolution-computing The mention sources can contact us to remove/changing this article |

What Are The Main Benefits Of Comparing Car Insurance Quotes Online

LOS ANGELES, CA / ACCESSWIRE / June 24, 2020, / Compare-autoinsurance.Org has launched a new blog post that presents the main benefits of comparing multiple car insurance quotes. For more info and free online quotes, please visit https://compare-autoinsurance.Org/the-advantages-of-comparing-prices-with-car-insurance-quotes-online/ The modern society has numerous technological advantages. One important advantage is the speed at which information is sent and received. With the help of the internet, the shopping habits of many persons have drastically changed. The car insurance industry hasn't remained untouched by these changes. On the internet, drivers can compare insurance prices and find out which sellers have the best offers. View photos The advantages of comparing online car insurance quotes are the following: Online quotes can be obtained from anywhere and at any time. Unlike physical insurance agencies, websites don't have a specific schedule and they are available at any time. Drivers that have busy working schedules, can compare quotes from anywhere and at any time, even at midnight. Multiple choices. Almost all insurance providers, no matter if they are well-known brands or just local insurers, have an online presence. Online quotes will allow policyholders the chance to discover multiple insurance companies and check their prices. Drivers are no longer required to get quotes from just a few known insurance companies. Also, local and regional insurers can provide lower insurance rates for the same services. Accurate insurance estimates. Online quotes can only be accurate if the customers provide accurate and real info about their car models and driving history. Lying about past driving incidents can make the price estimates to be lower, but when dealing with an insurance company lying to them is useless. Usually, insurance companies will do research about a potential customer before granting him coverage. Online quotes can be sorted easily. Although drivers are recommended to not choose a policy just based on its price, drivers can easily sort quotes by insurance price. Using brokerage websites will allow drivers to get quotes from multiple insurers, thus making the comparison faster and easier. For additional info, money-saving tips, and free car insurance quotes, visit https://compare-autoinsurance.Org/ Compare-autoinsurance.Org is an online provider of life, home, health, and auto insurance quotes. This website is unique because it does not simply stick to one kind of insurance provider, but brings the clients the best deals from many different online insurance carriers. In this way, clients have access to offers from multiple carriers all in one place: this website. On this site, customers have access to quotes for insurance plans from various agencies, such as local or nationwide agencies, brand names insurance companies, etc. "Online quotes can easily help drivers obtain better car insurance deals. All they have to do is to complete an online form with accurate and real info, then compare prices", said Russell Rabichev, Marketing Director of Internet Marketing Company. CONTACT: Company Name: Internet Marketing CompanyPerson for contact Name: Gurgu CPhone Number: (818) 359-3898Email: [email protected]: https://compare-autoinsurance.Org/ SOURCE: Compare-autoinsurance.Org View source version on accesswire.Com:https://www.Accesswire.Com/595055/What-Are-The-Main-Benefits-Of-Comparing-Car-Insurance-Quotes-Online View photos

to request, modification Contact us at Here or [email protected]